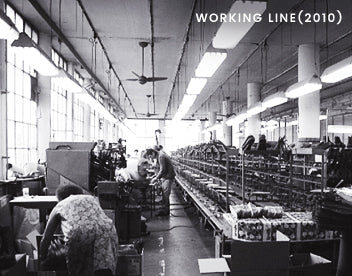

The manufacturing factories of Novesta date back to the 1930s, when the famous shoemaker Jan Antonín Baťa opened his new factory in a small town in the middle of Slovakia - in Partizánske. Novesta is one of the last purely European brands to remain operating in its original premises, working by the original method on good old-fashioned machines that require a great deal of precision handwork.

Sustainable heritage

Novesta products were and are designed to last as long as possible. Our traditional production method requires high quality materials (certified to the highest possible quality), which, combined with minimalist and timeless design, transcends fashion trends and allows for long-lasting use. In addition, many Novesta products can be washed or laundered. In spite of this, they also have replaceable insoles, which also contributes to the longer life of the individual products.

Sustainability at Novesta starts with sourcing raw materials from suppliers with transparent production cycles at fair prices. This includes sourcing VFCS-certified natural rubber from verified suppliers and GOTS-certified organic cotton uppers for our Star Master and Star Dribble models. Our Marathon model is also

designed to incorporate as much recycled synthetic mesh as possible and a sole made from certified natural rubber. At Novesta, we are extremely proud of the tradition, heritage and quality of our handmade footwear. We would be delighted if you would honour us with a visit or a purchase in our e-shop, featuring footwear from our latest collection.

The headquarters factory in Partizánske was the largest shoe factory in the former Czechoslovakia and produced rubber-soled shoes, such as exercise boots, work boots, sports shoes and rain boots for the army.

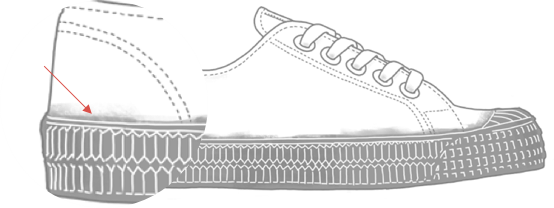

All Novesta soles are made of natural rubber. Natural rubber is a raw material that is mixed with chemicals to increase flexibility and durability, and then thoroughly kneaded with pigments for colouring. The carefully kneaded rubber is the keystone of the Star Master, which doesn't peel away from the upper and has astonishing strength. The rubber is folded like croissant dough and cut into shapes such as soles and rubber boots. In addition, the headquarters factory, which specialises in rubber for products, also produces tyres for European car tyre manufacturers and technical rubber for industrial products. The colourful sole of the Star Master model, which is famous for its wide range of colours, was born from the high level of technology and years of experience gained through consistent rubber production.

Any leftover rubber scraps cut from the sheet are recycled without being thrown away. The rubber offcuts are kneaded again and reborn into a new rubber sheet. Sustainability is one of Novesta's most important concepts. The process of producing high quality products while incorporating recycling into the process is constantly improving. The manufacturing headquarters is certified according to ISO 14001, the international standard for environmental issues.

True Novesta

Novesta's most popular model is the Star Master, which bears the hallmarks of a rubber impression and signs of vulcanisation that guarantee the authenticity of the shoe and its durability.